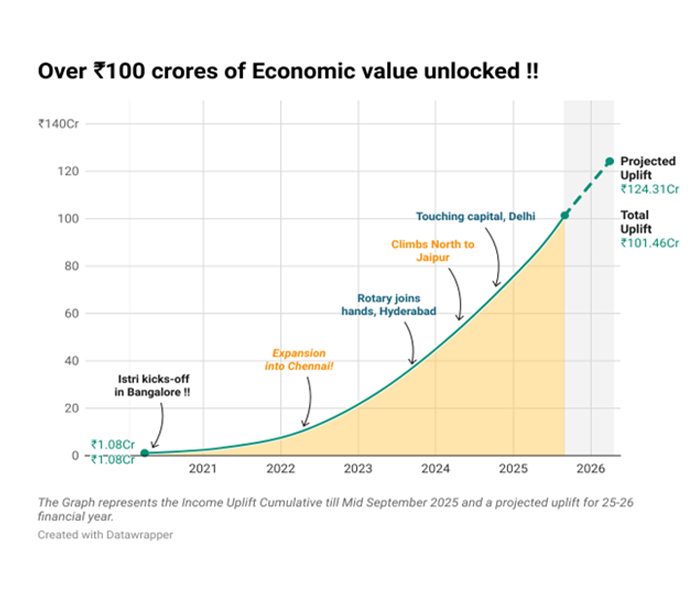

₹100CR Income Uplift for

Bharat's Nano-Entrepreneurs!

Through the Istri Project, 8,000+ ironing vendors across 5 cities have grown stronger, greener, and more self-reliant, powering the 90% economy.

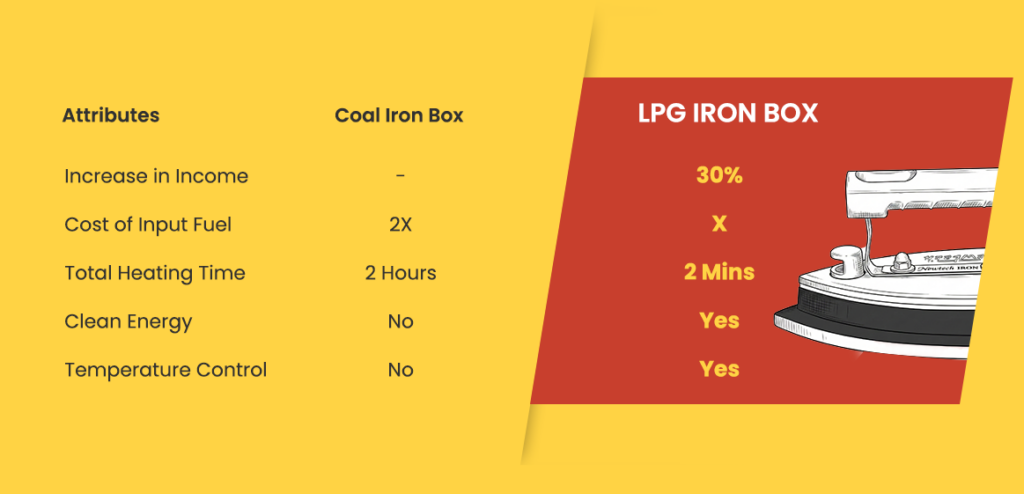

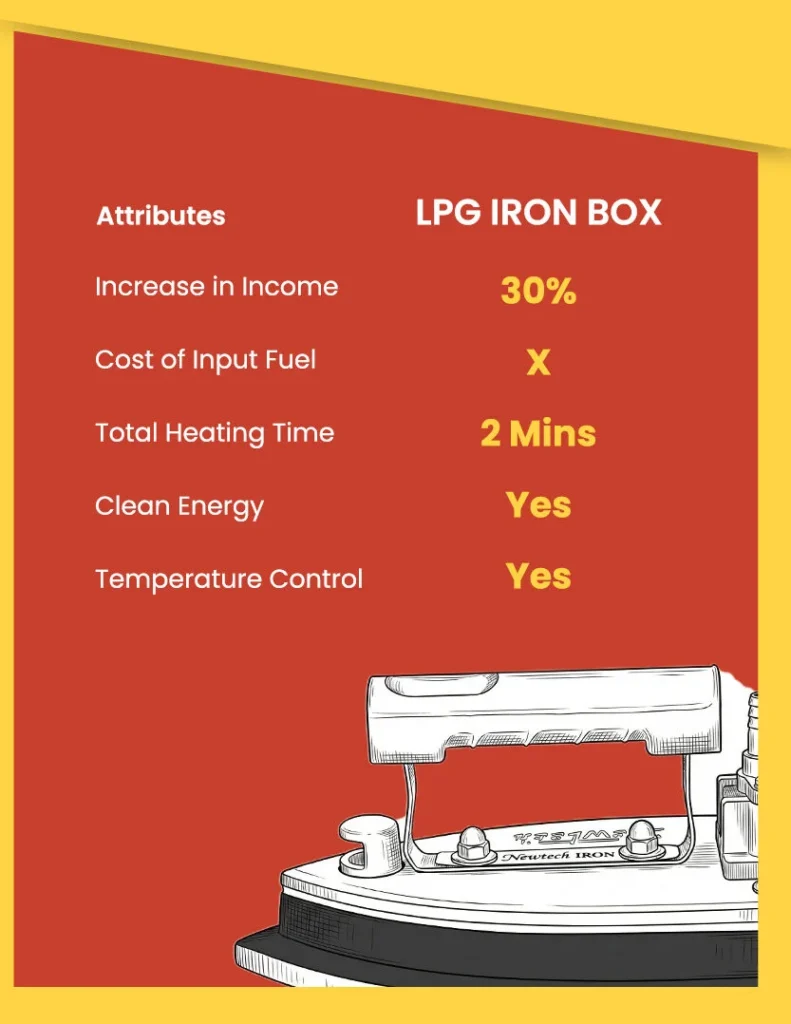

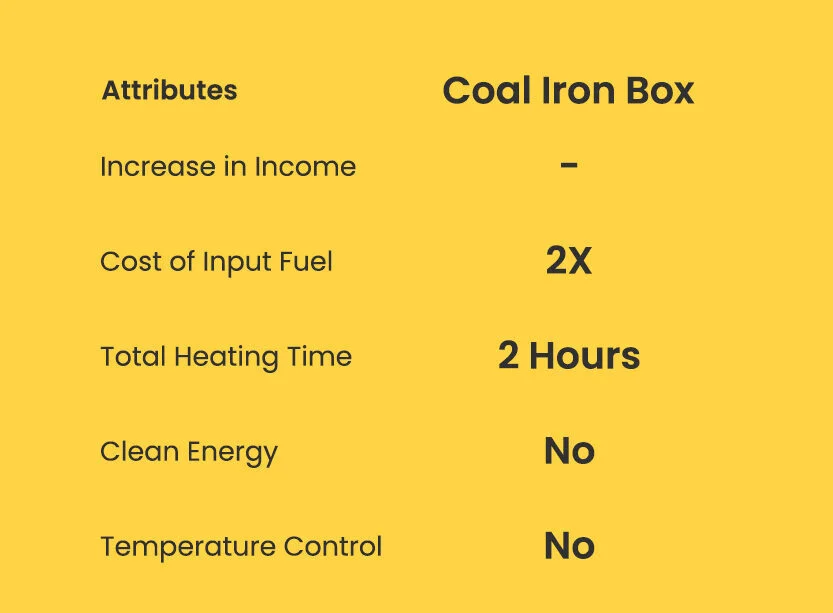

Every neighbourhood has that one ironing vendor who keeps our clothes crisp and our days sorted. Yet, behind every neatly pressed shirt lies an old coal iron box — heavy, smoky, and time-consuming. It not only releases harmful CO₂ but also eats up over 2 hours daily for the Ironing vendors, before work can even begin.

The Challenges

19th century solution to cater to modern day business demands

Heating coal iron box takes up to 2 hour daily

Reduced productivity Stagnation and efficiency in business

Rise in Coal Prices

The Solution

Most ironing vendors operate from streetside pushcarts to cater to their customers across different parts of the city. Due to the mobile nature of their work, they do not have access to a permanent electricity supply for their business. An LPG Iron box, connected to a commercial cylinder, changes how an ironing vendor operates their business.

Why LPG Iron Box

Systematic Approach to ensure Sustainability of Impact

To ensure each ironing vendor is able to adopt and sustain the use of the new LPG Ironbox, the transition process addresses the awareness, affordability, accessibility barriers and creates a post sale ecosystem to bring in sustainable impact.

The current approach addresses the

affordability, accessibility, and awareness barriers

to bring in sustainable ecosystem change

Demand

1.Sanghas, Last-mile to build product awareness

2.CSRs for incentivizing adoption through subsidies

3.Implementation Partners - for driving conversion

Market

1.Manufacturers to produce more, improve Quality

2.Retailers to stock more

3.Financers for subsidy & loans

4.Marketing Channels to enhance awareness

5.After-Sales service points

Sustenance

1.Strengthen After-Sales service

2.Measure Organic adoption of the new product

3.Create awareness of results

Demand

1. Sanghas, Last-mile to build product awareness

2. CSRs for incentivizing adoption through subsidies

3. Implementation Partners - for driving conversion

Market

1. Manufacturers to produce more, improve Quality

2. Retailers to stock more

3. Financers for subsidy & loans

4. Marketing Channels to enhance awareness

5. After-Sales service points

Sustenance

1. Strengthen After-Sales service

2. Measure Organic adoption of the new product

3. Create awareness of results

Impact So Far

(as on 29 January, 2026)

8,852

Entrepreneurs

Impacted

Rs. 424.90M

Annual

Income Uplift

27%

Income

Uplift

6,353

Tons CO2

Eliminated Yearly

635K

Trees Freed

Up Yearly

Our Reach

Bengaluru

Chennai

Hyderabad

Jaipur

Delhi

Impact Validated:

Independent Assessment

by Azim Premji University

A detailed third-party impact study revealed how Chennai’s ironing vendors are transforming their livelihoods. By switching from coal to LPG-based ironing boxes, they’ve achieved a 28% rise in monthly income while cutting fuel costs by nearly half.

Stakeholders

Manufacturers

and Distributers

Istri

Vyapaaris

Gas

Suppliers

Partner

and Funders

Way Ahead

There are an estimated 25000+ Coal-based Istri Vyapaaris in top 100 cities in India

*Commissioned third-party surveys

Our vision is to make India Coal

Iron box Free within the next decade.

Stories Of Impact

Venkatesh used a coal ironing box and earned INR 400-500 daily, but his income increased 1.4 times after transitioning to LPG ironing boxes as now he can iron more clothes. Finishing is perfect in the LPG iron box. He says, “Customers used to be unhappy with us whenever their clothes got burnt due to coal. Now we do not have any such problems. Further, coal has to be changed 4-5 times a day. This time can be saved if you use an LPG iron box. The best part of this iron box is that we can adjust the heat based on the type of clothes we are ironing.”

Venkatesh

Vyapaari

Rajesh didn’t just switch from a coal iron to an LPG iron box-he became a voice for safer and cleaner work practices. He sees this change as “the next step towards progress” for himself and his community. By choosing an LPG iron, he’s not only improving his own livelihood but also inspiring others in the trade to adopt better, healthier tools.

Rajesh

Vyapaari

The transition to an LPG iron box has significantly changed how I work. Working with coal used to leave my hands black, often staining the white clothes. The LPG iron box has eliminated this challenge. My customers are now happy and satisfied. Additionally, it heats up within just 5 minutes, saving me valuable time and ensuring customer satisfaction.

Saathesh

Bangalore based Vyapaari

“Within a few months, I noticed the astounding impact of using the LPG iron box, so I decided to buy a second one for my husband, who is also an ironing vyaapaari. The number of clothes we could iron per day increased from 150 to 300, leading to a significant upliftment in our income. Personally, I experienced a surge in confidence as I could now iron delicate clothes without the constant worry of burning them with cinder.

Satya

Bangalore based Vyaapaari

Kamlesh switched from a coal iron to an LPG iron box, giving her more control over her daily routine. Now, she decides when to eat, when to return home, how many clothes to iron, and how long to work. The LPG iron not only reduced her effort but also gave her back her time and independence.

Kamlesh

Vyapaari